Mashine ya Ubora ya CNC ya Kunyoa manyoya

1. Fremu nzima ya mashine inachakatwa na kituo cha usindikaji cha pentahedron cha Ujerumani SHW kwa wakati mmoja.

4. Pembe ya kunyoa inaweza kubadilishwa kwa urahisi kwa njia ya programu ili kuepuka deformation ya workpiece inayosababishwa na kukata.

5. Urefu wa kiharusi cha boriti ya juu unaweza kubadilishwa kiotomatiki ili kutambua kukata kwa haraka na kwa usahihi kwa kipande cha kazi kifupi na kidogo ili kuboresha ufanisi wa kazi.

6. Mfumo wa CNC utarekebisha kiotomati pengo la vile kulingana na unene tofauti wa karatasi na nyenzo ili kuboresha ubora wa kukata.

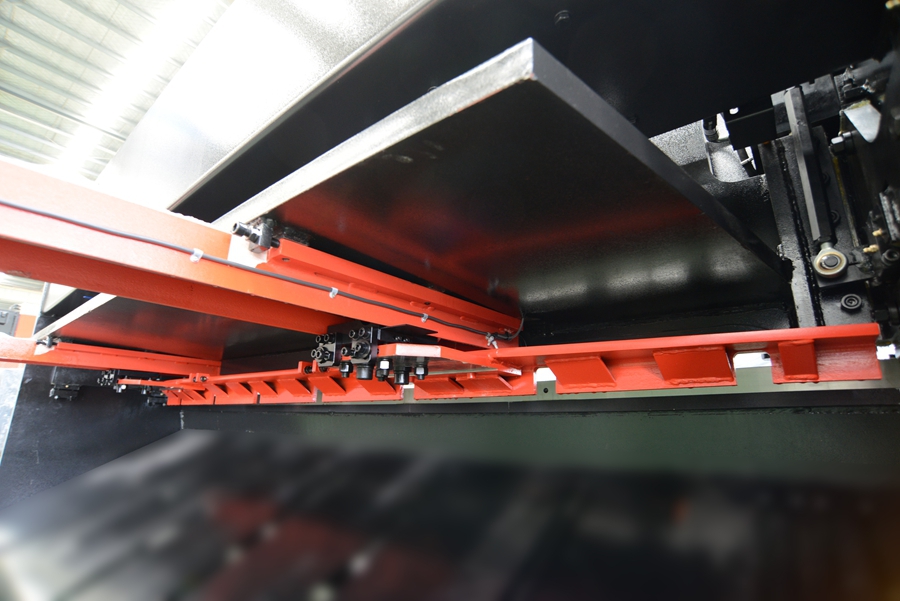

7. Kisu cha kukata nywele nne kinachukuliwa ili kuboresha maisha ya huduma ya blade ambayo ni bora zaidi kuliko ile ya swing shear.

8, Muundo mpya wa backgauge, muundo thabiti, kuboresha upinzani wa kuvaa, kustahimili ajali nyingi

2. Inapitisha mfumo wa Delem DAC360 CNC:

● dhibiti kwa usahihi urejeshaji

●dhibiti kwa usahihi kiharusi cha kukata nywele

● dhibiti kwa usahihi pembe ya kukata manyoya

●dhibiti kwa usahihi uondoaji wa vile

●dhibiti idadi ya kazi kwa usahihi.

3. Inapitisha mfumo wa majimaji wa BOSCH wa Ujerumani:

● kurahisisha bomba

●kuepusha mafuta kuvuja

● kuboresha uthabiti wa kufanya kazi

● kupamba mwonekano wa mashine

1. hutumika kwa udhibiti wa kiotomatiki wa mashine ya kukata manyoya yenye ulaji wa mbele au kifaa cha nyuma kinachofanya kazi kikamilifu.

2. inachukua ufafanuzi wa juu wa onyesho la LCD, upangaji wa aina ya menyu;

3. pembe ya kukata manyoya, pengo la blade, hesabu na udhibiti wa kiharusi cha kukata manyoya;

4. ujenzi wa msimu, ufafanuzi unaonyumbulika au kupanua udhibiti wa kulisha uliosawazishwa wa X1-X2 na udhibiti wa mhimili msaidizi wa Z;

5. inachukua nafasi kamili na programu ya nafasi ya jamaa;

6. utafutaji otomatiki wa uhakika wa kumbukumbu, na nafasi ya mbali ya kumbukumbu inaweza kuweka;

7. muundo wa kipekee wa gurudumu la mkono kufanya marekebisho ya mashine kwa urahisi;

8. RS232 interface ya serial;

9. pato la ishara nyingi za msaidizi zilizofafanuliwa na mtumiaji;

10. mpango wa utambuzi wa kibinafsi;

11. uhifadhi wa ndani wa mstari wa programu 100;

12. 4.7 inchi ya ufafanuzi wa juu wa LCD;

13. kazi ya kuhesabu programu;

14. uteuzi wa kitengo cha ukubwa kati ya mfumo wa metri na mfumo wa Kiingereza.

| Hapana. | Kipengee | Kiasi. | Toa maoni |

| 1 | Faili za Mashine | Seti moja | |

| 2 | Hex Soketi Spanner | Seti moja | |

| 3 | Grise Gun | Nambari moja. | |

| 4 | Bolt ya Kutuliza | Seti moja | |

| 5 | Kurekebisha Bolt | Seti moja | |

| 6 | Udhibiti wa Mguu | Nambari moja. |

1. Chanzo cha hewa: hakikisha shinikizo la gesi linalotolewa kwa mashine inapaswa kuwa zaidi ya 0.6 Mpa, mtiririko wa gesi unapaswa kuwa zaidi ya 0.3 m3 / min.

2. Mafuta ya Hydraulic: VG46 # anti-wear hydraulic oil iliyoagizwa. Kiasi kinachohitajika cha mafuta kimewekwa hapa chini:

| Mfano wa Mashine | Misa ya Mafuta (L) |

| VR6, VR8 mfululizo | 230 |

| mfululizo wa VRZ | 690 |

| Mfululizo wa VR10 | 370 |

| VR13*3200 | 460 |

| VR13*6200 | 800 |

3.Nguvu: 380V,50HZ, kushuka kwa voltage ±10%

4. Halijoto ya mazingira: 0°C - +40°C

5. Unyevu wa mazingira: unyevu wa kiasi 20-80%RH(usio mgandamizo)

6. Weka mbali na chanzo chenye nguvu cha mtetemo na mwingiliano wa sumakuumeme

7. Vumbi kidogo, hakuna gesi hatari au babuzi

8. Kuandaa msingi kulingana na kuchora msingi

9. Chagua wafanyikazi jamaa walio na historia fulani ya elimu kwa mpangilio wa muda mrefu kama mendesha mashine.

Mashine ya Kukata manyoya ya CNC; kukata manyoya ya hydraulic guillotine; mashine ya kunyoa; kukata nywele kwa cnc

2500

| Maelezo | Kitengo | 6*2500 | |

| Unene wa Kunyoa (mm) | Chuma kidogo 450Mpa | mm | 0.5-6 |

| Chuma cha pua 600Mpa | 0.5-4 | ||

| Alumini 300Mpa | 0.5-8 | ||

| Urefu wa Kunyoa | mm | 2500 | |

| Pembe ya Kunyoa | ° | 0.5°~2° | |

| Nyuma- kipimo | Kiharusi mm | mm | 5 ~ 1000 |

| Kasi mm/s | mm/s | ≤250 | |

| Usahihi mm | mm | ±0.1 | |

| Servo Motor Power KW | KW | 1 | |

| Nyakati za Kiharusi | hpm | 25-36 | |

| Uwezo wa Silinda (L) | L | 230 | |

| Idadi ya Clamping | hapana. | 12 | |

| Nguvu Kuu ya Magari (KW) | KW | 11 | |

| Mfumo wa CNC | Mfumo wa Holland Delem DAC360 CNC unaodhibiti pembe ya kukata manyoya, pengo la vile, na kiharusi cha kukata nywele. | ||

| Nambari na urefu wa mkono wa msaada (mm) | mm | 3*1400 | |

| Vipimo vya Muhtasari | Urefu (mm) | mm | 3110 |

| Upana (mm) | mm | 3000 | |

| Urefu (mm) | mm | 1705 | |

3000/3200

| Maelezo | Kitengo | 6*3000 | 8*3000 | 10*3000 | 13*3200 | 16*3200 | ||||

| Unene wa Kunyoa (mm) | Chuma kidogo 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||

| Chuma cha pua 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||

| Alumini 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||

| Urefu wa Kunyoa | mm | 3070 | 3070 | 3070 | 3200 | 3200 | ||||

| Pembe ya Kunyoa | ° | 0.5 ° -2 ° | 0.5 ° -2 ° | 0.5 ° -2 ° | 0.5 ° -2 ° | 0.5 ° -2 ° | ||||

| Nyuma- kipimo | Kiharusi mm | mm | 5 ~ 1000 | 5 ~ 1000 | 5 ~ 1000 | 5-1000 | 5-1000 | |||

| Kasi mm/s | mm/s | ≤250 | ≤250 | ≤250 | 200 | 200 | ||||

| Usahihi mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||

| Servo Motor Power KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||

| Nyakati za Kiharusi | hpm | 22-35 | 16-34 | 15-32 | 10-15 | 9-16 | ||||

| Uwezo wa Silinda (L) | L | 230 | 230 | 370 | 460 | 460 | ||||

| Idadi ya Clamping | hapana. | 14 | 14 | 14 | 15 | 15 | ||||

| Nguvu Kuu ya Magari (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||

| Mfumo wa CNC | Mfumo wa Holland Delem DAC360 CNC unaodhibiti pembe ya kukata manyoya, pengo la vile, na kiharusi cha kukata nywele. | |||||||||

| Nambari na urefu wa mkono wa msaada (mm) | mm | 3*1400 | 3*1400 | 3*1400 | 3*1000 | 3*1000 | ||||

| Vipimo vya Muhtasari | Urefu (mm) | mm | 3610 | 3640 | 3720 | 4075 | 4300 | |||

| Upana (mm) | mm | 3000 | 3000 | 3040 | 2752 | 3000 | ||||

| Urefu (mm) | mm | 1705 | 1755 | 1880 | 2432 | 2850 | ||||

4000

| Maelezo | Kitengo | 6*4000 | 8*4000 | 10*4000 | 13*4000 | 16*4000 | ||||||

| Unene wa Kunyoa (mm) | Chuma kidogo 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||||

| Chuma cha pua 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||||

| Alumini 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||||

| Urefu wa Kunyoa | mm | 4070 | 4070 | 4070 | 4000 | 4000 | ||||||

| Pembe ya Kunyoa | ° | 0.5°~2° | 0.5°~2° | 0.5°~2° | 0.5°~2.5° | 0.5°~2.5° | ||||||

| Nyuma- kipimo | Kiharusi mm | mm | 5 ~ 1000 | 5 ~ 1000 | 5 ~ 1000 | 5-1000 | 5-1000 | |||||

| Kasi mm/s | mm/s | ≤250 | ≤250 | ≤250 | ≤200 | ≤200 | ||||||

| Usahihi mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||||

| Servo Motor Power KW | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||||

| Nyakati za Kiharusi | hpm | 16-34 | 14-32 | 12-32 | 10-15 | 8-15 | ||||||

| Uwezo wa Silinda (L) | L | 230 | 230 | 370 | 460 | 460 | ||||||

| Idadi ya Clamping | hapana. | 18 | 18 | 18 | 19 | 19 | ||||||

| Nguvu Kuu ya Magari (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||||

| Mfumo wa CNC | Mfumo wa Holland Delem DAC360 CNC unaodhibiti pembe ya kukata manyoya, pengo la vile, na kiharusi cha kukata nywele. | |||||||||||

| Nambari na urefu wa mkono wa msaada (mm) | mm | 4*1400 | 4*1400 | 4*1400 | 4*1000 | 4*1000 | ||||||

| Vipimo vya Muhtasari | Urefu (mm) | mm | 4610 | 4640 | 4720 | 4970 | 5300 | |||||

| Upana (mm) | mm | 3000 | 3000 | 3040 | 2760 | 3000 | ||||||

| Urefu (mm) | mm | 1705 | 1705 | 1880 | 2562 | 2850 | ||||||

6000/6200

| Maelezo | Kitengo | 6*6000 | 8*6000 | 13*6200 | 16*6000 | 16*6200 | |||

| Unene wa Kunyoa (mm) | Chuma kidogo 450Mpa | mm | 0.5~6 | 0.8~8 | 1-13 | 1-16 | 1-16 | ||

| Chuma cha pua 600Mpa | 0.5~4 | 0.8~5 | 1-8 | 1-10 | 1-10 | ||||

| Alumini 300Mpa | 0.5~8 | 0.8~10 | 1-18 | 1-20 | 1-20 | ||||

| Urefu wa Kunyoa | mm | 6140 | 6140 | 6200 | 6000 | 6200 | |||

| Pembe ya Kunyoa | ° | 0.5˚-2˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2˚ | |||

| Nyuma- kipimo | Kiharusi mm | mm | 5-1000 | 5-1000 | 5-1000 | 5-1000 | 5-1000 | ||

| Kasi mm/s | mm/s | 200 | 200 | 200 | 200 | 200 | |||

| Usahihi mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |||

| Servo Motor Power KW | KW | 1.0 | 1.0 | 1.0 | 1.5 | 2.0 | |||

| Nyakati za Kiharusi | hpm | 12-20 | 12-20 | 6-10 | 5-9 | 5-9 | |||

| Uwezo wa Silinda (L) | L | 690 | 690 | 800 | 800 | 800 | |||

| Idadi ya Clamping | hapana. | 29 | 29 | 27 | 27 | 27 | |||

| Nguvu Kuu ya Magari (KW) | KW | 11 | 15 | 30 | 37 | 37 | |||

| Mfumo wa CNC | Mfumo wa Holland Delem DAC360 CNC unaodhibiti pembe ya kukata manyoya, pengo la vile, na kiharusi cha kukata nywele. | ||||||||

| Nambari na urefu wa mkono wa msaada (mm) | mm | 6*1000 | 6*1000 | 6*1000 | 6*1000 | 6*1000 | |||

| Vipimo vya Muhtasari | Urefu (mm) | mm | 7055 | 7115 | 7220 | 7300 | 7500 | ||

| Upana (mm) | mm | 2686 | 2690 | 2945 | 3000 | 3000 | |||

| Urefu (mm) | mm | 2495 | 2680 | 2850 | 2850 | 2850 | |||

VR(Z)Mfululizo:

| Hapana. | Jina | Mfano | Chapa |

| 1 | Mfumo wa CNC | Mfumo wa CNC wa DAC360 | Uholanzi Delem |

| 2 | Servo Motor | EMJ-10APB22 | Estun |

| 3 | Dereva wa Servo | RONET-E-10A-AMA | Estun |

| 4 | Mfumo wa Hydraulic | Seti ya valve ya hydraulic ya electro-servo | Ujerumani Bosch-Rexroth |

| a.vali ya shinikizo sawia | |||

| b. valve ya cartridge | |||

| c.vali ya kiteuzi ya sumakuumeme | |||

| d. vali ya shinikizo inayofunika | |||

| e.udhibiti wa majimaji wa vali ya njia moja | |||

| f. valve ya koo | |||

| e.valli ya njia moja nk. | |||

| 5 | Njia ya mstari | HSR25A-1240L | THK au PMI |

| 6 | Mipira | 25/20-1400mm | THK au PMI |

| 7 | Pampu ya mafuta | IPH-5B-50-11 au PGH4-3X/050-E11VU2 | Japan NACHI pampu au Ujerumani Rexroth |

| 8 | Seti kamili ya pete ya kuziba kwenye silinda ya mafuta | USA PARKER | USA PARKER |

| 9 | Seti kamili ya bomba la shinikizo la juu | 1.F372C91C161608-1200mm | USA PARKER、EO-2 bomba pamoja au Ujerumani VOSS bomba pamoja |

| 2 (F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4 (F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Au F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF nk. | |||

| 10 | Kuunganisha | R38 25.385/42 nk. | Ujerumani KTR |

| 11 | Kiunganisha cha AC | LC1-D38B7C, LC1-D25B7Cetc. | Schneider |

| 12 | Kubadili ukaribu | TP-SM5P2 na kadhalika. | TENDA |

| 13 | Uongozi wa terminal | TB2.5B TB16ICH nk. | Phoenix |

| 14 | Kitufe | XB2-BVB3LC nk. | Schneider |

| 15 | Uchoraji | KAILEDI |

VR(Z)Mfululizo:

| Hapana. | Jina | Mfano | Chapa |

| 1 | Mfumo wa CNC | Mfumo wa CNC wa DAC360 | Uholanzi Delem |

| 2 | Servo Motor | EMJ-10APB22 | Estun |

| 3 | Dereva wa Servo | RONET-E-10A-AMA | Estun |

| 4 | Mfumo wa Hydraulic | Seti ya valve ya hydraulic ya electro-servo | Ujerumani Bosch-Rexroth |

| a.vali ya shinikizo sawia | |||

| b. valve ya cartridge | |||

| c.vali ya kiteuzi ya sumakuumeme | |||

| d. vali ya shinikizo inayofunika | |||

| e.udhibiti wa majimaji wa vali ya njia moja | |||

| f. valve ya koo | |||

| e.valli ya njia moja nk. | |||

| 5 | Njia ya mstari | HSR25A-1240L | THK au PMI |

| 6 | Mipira | 25/20-1400mm | THK au PMI |

| 7 | Pampu ya mafuta | IPH-5B-50-11 au PGH4-3X/050-E11VU2 | Japan NACHI pampu au Ujerumani Rexroth |

| 8 | Seti kamili ya pete ya kuziba kwenye silinda ya mafuta | USA PARKER | USA PARKER |

| 9 | Seti kamili ya bomba la shinikizo la juu | 1.F372C91C161608-1200mm | USA PARKER、EO-2 bomba pamoja au Ujerumani VOSS bomba pamoja |

| 2 (F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4 (F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Au F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF nk. | |||

| 10 | Kuunganisha | R38 25.385/42 nk. | Ujerumani KTR |

| 11 | Kiunganisha cha AC | LC1-D38B7C, LC1-D25B7Cetc. | Schneider |

| 12 | Kubadili ukaribu | TP-SM5P2 na kadhalika. | TENDA |

| 13 | Uongozi wa terminal | TB2.5B TB16ICH nk. | Phoenix |

| 14 | Kitufe | XB2-BVB3LC nk. | Schneider |

| 15 | Uchoraji | KAILEDI |